Schon unsere aktuelle Profi-Aktion gesehen? Jetzt klicken und mehr erfahren!

INDUSTRY | METAL

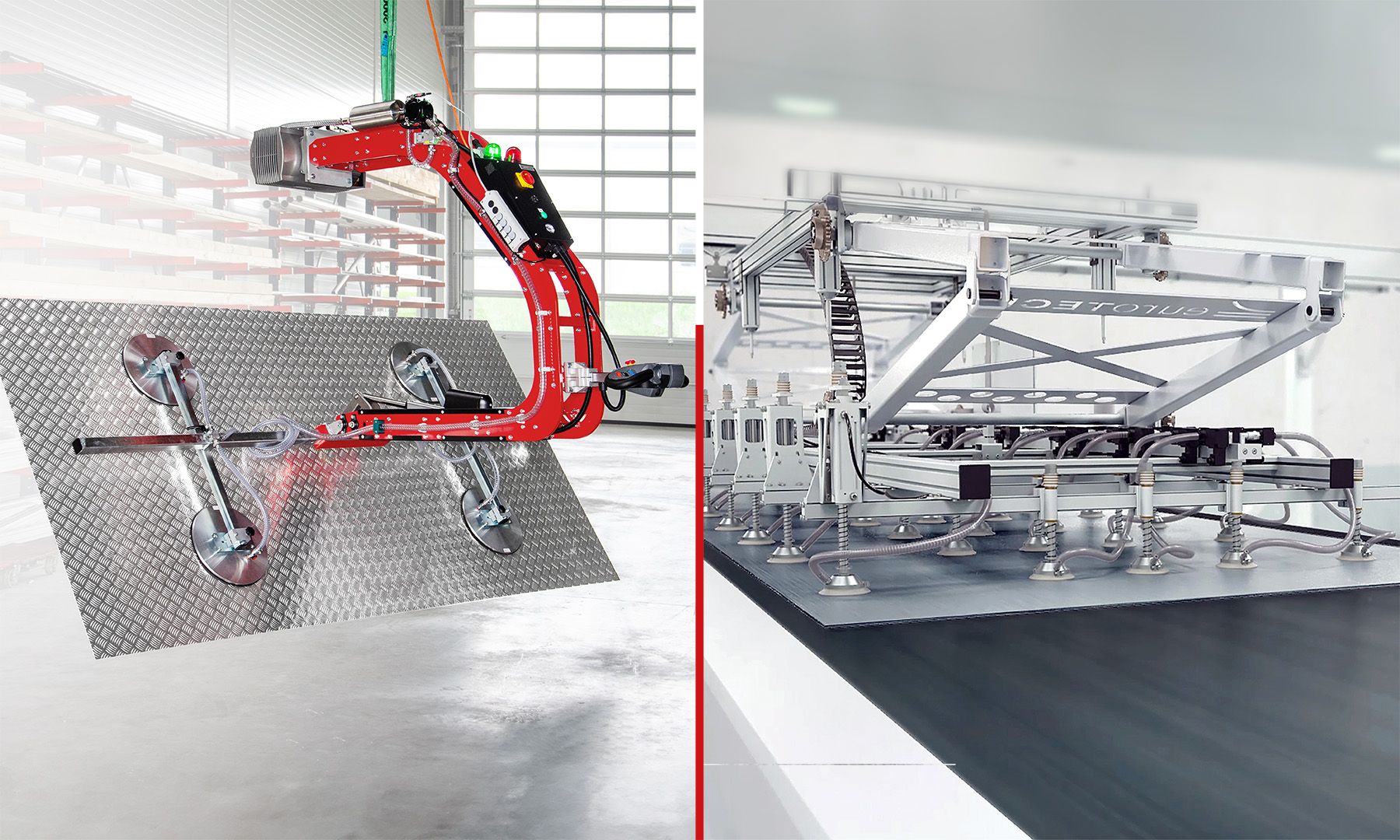

euroTECH handling solutions

for the metal industry

We move metal

Moving metal plates or parts is a complex task. In addition to avoiding the risk of injury, it is important to adapt precisely to the respective material properties and surfaces.

As in the glass sector, the protective covers and specially designed suction cups prove their worth here, too, in order to lift gently and without leaving marks. In addition, heavy weights can quickly occur that need to be moved safely.

The euroTECH vacuum units are developed in such a way that all metal surfaces and heavy loads can be reliably and gently suctioned in order to lift, pick, transport and precisely place them.

Our handling technology integrates seamlessly into the frequently automated processes of metalworking, whether as a lifting device, gantry or robotic extension. Our handling solutions and components have a modular and flexible design so that they can be adapted to your specific requirements.

Together with you, we develop and implement economical and customized transport and handling solutions that are precisely tailored to the requirements and properties of your workpieces, such as surface, density and size.

Safe and productive with vacuum technology

euroTECH supports agricultural machinery manufacturer CLAAS with vacuum lifting technology. In the manufacture of agricultural vehicles, great importance is attached to individual configuratio...

Vacuum sheet metal handling - an investment in the future

At this year's Blechexpo trade fair in Stuttgart from November 7 to 10, euroTECH will be presenting a selection of its products in Hall 5, Stand 5506. The company...

The fine art of panel handling

Many sheet metal processing companies are slowly reaching their limits when it comes to handling panels safely and in a space-saving manner. euroTECH, the specialist in...