Schon unsere aktuelle Profi-Aktion gesehen? Jetzt klicken und mehr erfahren!

Plant engineering

Customer-oriented handling solutions

eT-Matic

Portals

Integrating our innovative lifting technology into your loading, picking or stacking systems improves safety, increases efficiency and reduces costs.

Our handling solutions are as diverse and cross-technology as your individual requirements and products demand.

eT-Sol

Solar testing systems

With eT-Sol, euroTECH implements your own high-performance simulation and testing system, which has a modular structure and is flexibly adapted to your testing tasks.

Having your own test system in your factory makes you independent of external tests and guarantees the highest quality standards during implementation.

eT-Robotics

Robotics

Our tailor-made and individual lifting technology solutions are a valuable addition for optimizing your robot systems.

For smaller applications where space saving is important, we offer you the ideal collaborative robot with Cobot Lift.

Top-class plant engineering in euroTECH quality

Our experienced team accompanies you from the initial idea to the commissioning of your system and ensures that all processes mesh perfectly. We check the feasibility of our customers' wishes and use our experience to achieve the optimum design. As soon as the concept is ready, we get to work on implementation.

Our customers benefit from the proven euroTECH guiding principle: everything from a single source and everything from practice - for practice! Our system solutions are tailor-made, customer-oriented productions in the proverbial quality. We integrate our tried-and-tested standard modules at suitable points to ensure maximum efficiency, maximum functionality and excellent service.

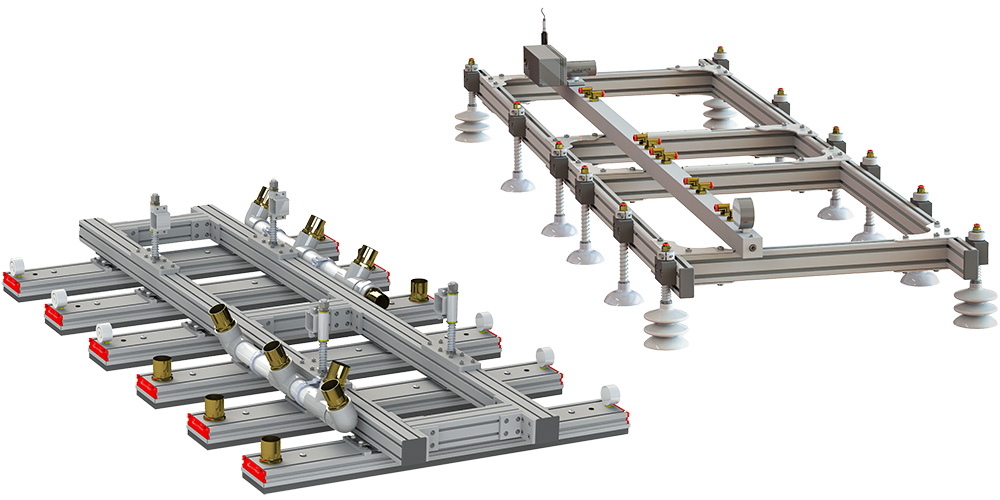

eT-Matic

Portals

Regardless of whether it is a modification to a standard device or a completely customized system - we have the optimum application for every use case. Based on our many years of project experience and the extensive know-how of our design engineers and experts, we develop innovative handling solutions of the highest quality from a single source. In addition to proven vacuum technology, we also use other technologies such as needle grippers.

Areas of application

- Feeding systems

- Picking systems

- Stacking systems

- Partially and fully automated systems

- Lifting and running gear

- Suction frame

Advantages

- Acceleration of work processes

- Increasing efficiency and profitability

- Protection of the loads

- Minimizing the risk of injury in the workplace

- Flexibility and versatility of application areas

- Long-term cost savings

Everything from a single source

All relevant work steps for the realization of your individual handling and transport solution take place in-house:

- Project planning

- Construction

- Mechanics

- Electrical engineering

- Vacuum and needle gripping technology

- Automation

- Quality management

- Customer service

This guarantees the highest quality, flexibility and reliability.

eT-Sol

Your individual solar testing systems

With eT-Sol, euroTECH realizes your own high-performance simulation and testing system, modularly constructed and flexibly adapted to your test tasks.

Having your own test facility in your factory makes you independent of external tests and gives you the security of the highest quality standards. At the same time, you can significantly shorten development processes, minimize risks and reduce production costs.

Advantages

- Individual test and simulation procedures for mechanical loads such as snow and wind load

- Testing in accordance with DIN IEC 61215-2:2021 + IEC 62782:2016

- Measurements of test forces far beyond the standard

- Frequency up to 4Hz (standard 0.1 Hz) i.e. up to 240 pull/push cycles per minute.

- Precise presentation of test values for complete documentation

- Data export to csv for Labview

- Independent of external test procedures and certification bodies

- Shortening the development process for solar modules

eT-Robotics

Robotics

Automation is one of the most important keys to sustainable success in the modern working world. Intelligent vacuum technology ideally complements this requirement. Collaborative robots (cobots) take the strain off people and increase efficiency. Our vacuum technology offers the perfect interface for safe material pick-up.

Optimize your lifting and transport robotics with our supplementary handling solutions.

Wherever smaller applications are required and space saving is crucial, our Cobot Lift will inspire you.

Lifting technology

for your robotics

Our customized and individual lifting technology solutions are a valuable addition to your robot systems. A successful implementation helps to improve and increase the efficiency of your robotics. Our lifting devices and handling solutions are developed and adapted to your specific needs so that they can be easily and adaptively integrated into your robot systems.

Our suction frames with vacuum components, in combination with robotics, offer a particular increase in automation efficiency in areas such as manufacturing, wood, glass and sheet metal processing and many other industries. Our eT-Grippers are specially designed to grip objects over their entire surface instead of gripping them selectively.

Lifting unit

Cobot Lift

Together with our robotics partner, we have created an automated lifting unit that combines our eT-Lift tube lifter with a collaborative robot. The result is maximum flexibility and mobility for automated lifting of up to 45 kg. The compact size saves valuable space. Cobot Lift enables continuous collaboration between man and machine. The operating personnel can safely remove loads without having to pay much attention to the Cobot Lift.

The mobile Cobot Lift lifts 10 kg and integrates the robot, controller, hand-held programming device, lifting hose and pump as well as a crane in a single unit.

The stationary cobot lift is permanently mounted on the floor. It increases the payload of the cobot from 10 to 45 kg and is ideal for collaborative palletizing and depalletizing or for pick[&]place tasks.

euroTECH develops solar test bench 4.0

Panels and collectors make an important contribution to the energy transition. With the increasing number of manufacturers and distributors of modules and superstructures,...

Let Robi do that!

The combination of a collaborative robot and state-of-the-art vacuum technology is the ultimate when it comes to relieving the strain on people during lifting work.

Alu-Point relies on automatic saw feed from euroTECH

The company Alu-Point, based south of Hanover, has succeeded in using an automatically controlled saw feed system from euroTECH Handling GmbH to ...