Schon unsere aktuelle Profi-Aktion gesehen? Jetzt klicken und mehr erfahren!

Info & Download

Monika Schuster

Monika Schuster

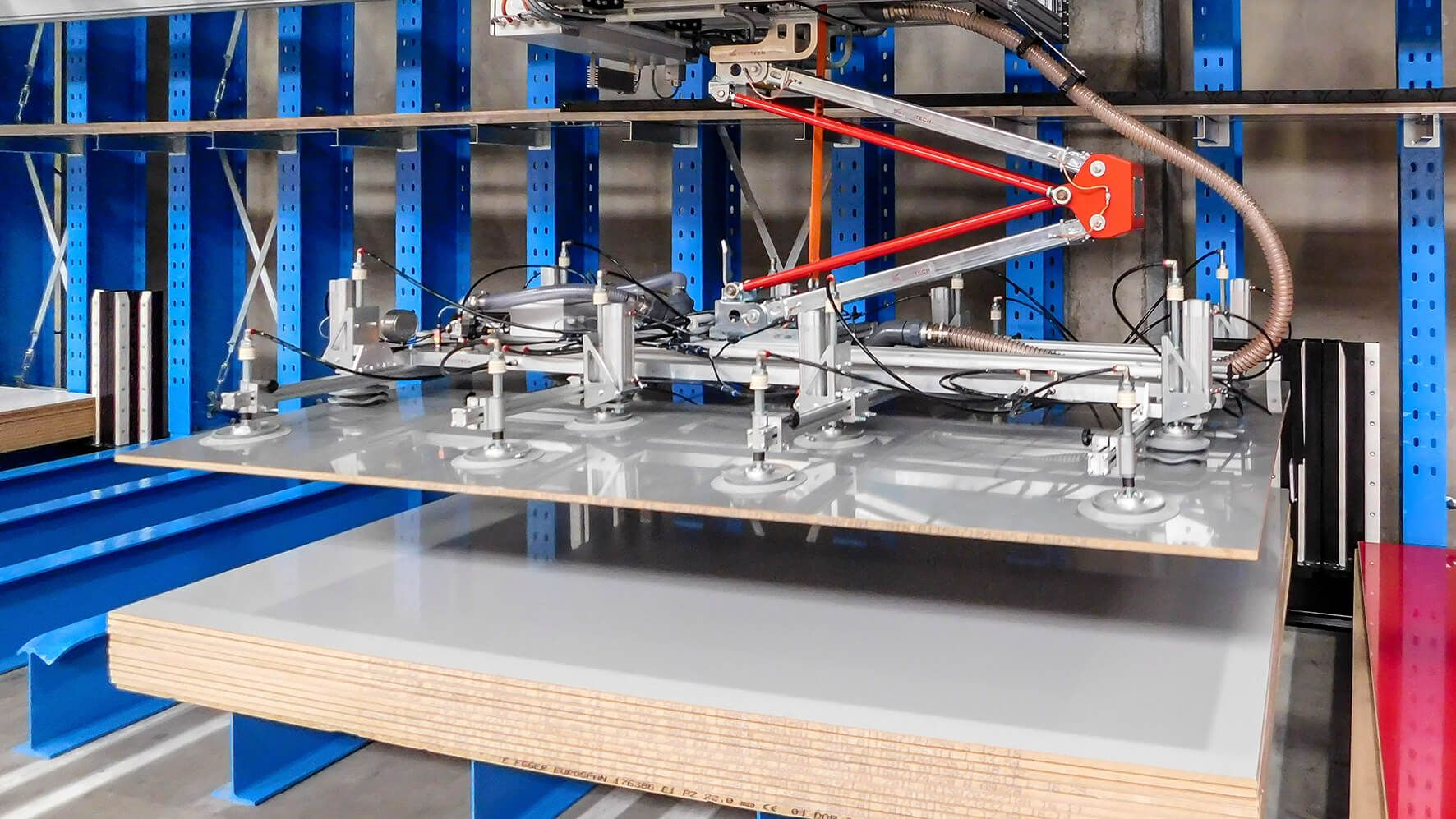

Order picking with vacuum technology - euroTECH offers complete solutions

The term "batch size 1" is becoming increasingly common in the production and handling of sheet goods. Many customers of large panel manufacturers only want or are only able to purchase very small quantities. Rising storage space costs are just one of the reasons for this. Many panel manufacturers are therefore looking for a solution for their order picking work. euroTECH has already developed several applications for this area. From rack storage systems with integrated vacuum order pickers to individual solutions, the specialist for vacuum lifting technology offers the ideal solution for many tasks.

In the time it used to take to produce a single panel, it is now possible to produce many times more. These shorter production cycles also increase the output of the systems. The market is oversaturated with sheet goods of all types, materials, colors and finishes. Fashion aspects also play a major role in today's world. What is modern today may soon be "old hat" again and the customer will be looking for a new decor.

Panel manufacturers then reach their limits. Due to the oversaturation of the market, the customer has an enormous choice. As a result, sales of a single type of panel are not particularly high. A lot is ordered in small quantities. If these slabs are then picked by hand, quality and health are at risk. On the one hand, several employees are needed to carry the boards and, on the other, high-gloss decors can hardly be stacked by hand without causing damage.

This is where euroTECH's vacuum technology comes into play. A vacuum picking device, which sucks in the boards and can lift them without them shifting or slipping, not only ensures consistent quality, but also reduces the physical strain on the employees who previously picked the boards by hand.

The boards are picked, fitted with protective plates and packed fully automatically. Only one person is needed to operate the system. If the company works with a cantilever rack, only one other employee has to load the various picking stations alternately with pallets of different panel goods.

The order picker starts with a protective plate on the customer pallet to protect the goods from damage. While the protective plate is in place, another pallet with plates of type A is placed at a free station on the shelf. The euroTECH picking system picks up the ordered boards one by one and places them on the customer pallet. During this process, the next station on the shelf is simultaneously loaded with a pallet of a different type of board. This can now be picked. At the same time as a pallet is picked, a space on the shelf is always emptied and a new type of board is placed in it. When an order has been completely picked, the vacuum device places another protective plate on the stack. The customer pallet can now be picked up and taken for packing.

Picking solutions from euroTECH not only protect the health and safety of employees and ensure the quality of goods, but also increase the efficiency of shipping.

Characters incl. spaces: 3,448, two images, reprint free