Schon unsere aktuelle Profi-Aktion gesehen? Jetzt klicken und mehr erfahren!

Info & Download

Monika Schuster

Monika Schuster

Nesting with 999 bellows suction cups - euroTECH builds suction box eT-Gripper for use on robots

This task can be made easy with the help of vacuum technology. For use in a nesting system, euroTECH has developed a special-sized suction box from the eT-Gripper product family that works in combination with a robot.

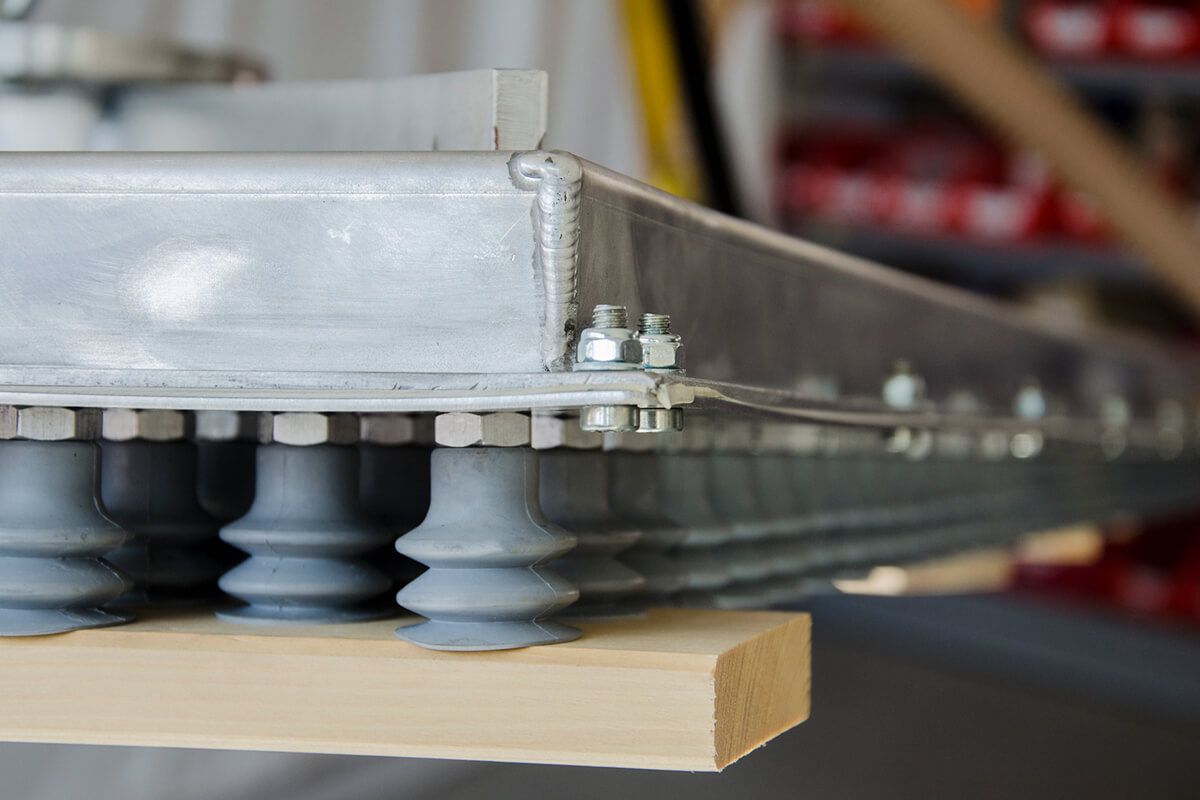

The suction box, built for a renowned furniture manufacturer and glass processor, is made of aluminum and is used on a robot. It removes a complete layer of cut furniture components from a nesting system and places them ready for sorting and further processing.

Thanks to the bellows suction cups, the eT-Gripper is able to separate a wide variety of shapes from the ten to twelve millimeter thick chipboard. Round parts are just as unproblematic as straight drawer fronts. Even larger parts, such as doors, are no problem for the suction box, as it has dimensions of 800 x 2400 millimetres and is therefore considerably larger than its eT-Gripper family members. A total of 999 BSC 32 E bellows suction cups were installed in it.

The bellows vacuum cleaners are preferable to a suction mat for this task, as they can be operated individually depending on the shape of the part to be vacuumed. This means that any material around the parts that is not required is not sucked up, remains in place and can simply be disposed of once all the parts have been removed.

Despite the enormous size of the suction box, its weight was kept relatively low by using a thin profile. In conjunction with the design of the customer's robot holder and the suction box itself, it is able to hold a maximum of 80 kg in this configuration.

With its optimized and reliable holding force, the eT-Gripper product family from euroTECH is suitable for use in various industries and sectors. Users benefit from the euroTECH modular system with its large number of combination and add-on systems. The vacuum specialist supplies both standard and customized vacuum grippers for a wide range of applications. When many parts have to be sawn, laser-cut or punched out of a panel and then separated, manual removal of the individual parts is often very laborious and time-consuming.

This task can be made easy with the help of vacuum technology. For use in a nesting system, euroTECH has developed a special-sized suction box from the eT-Gripper product family that works in combination with a robot.

The suction box, built for a renowned furniture manufacturer and glass processor, is made of aluminum and is used on a robot. It removes a complete layer of cut furniture components from a nesting system and places them ready for sorting and further processing.

Thanks to the bellows suction cups, the eT-Gripper is able to separate a wide variety of shapes from the ten to twelve millimeter thick chipboard. Round parts are just as unproblematic as straight drawer fronts. Even larger parts, such as doors, are no problem for the suction box, as it has dimensions of 800 x 2400 millimetres and is therefore considerably larger than its eT-Gripper family members. A total of 999 BSC 32 E bellows suction cups were installed in it.

The bellows vacuum cleaners are preferable to a suction mat for this task, as they can be operated individually depending on the shape of the part to be vacuumed. This means that any material around the parts that is not required is not sucked up, remains in place and can simply be disposed of once all the parts have been removed.

Despite the enormous size of the suction box, its weight was kept relatively low by using a thin profile. In conjunction with the design of the customer's robot holder and the suction box itself, it is able to hold a maximum of 80 kg in this configuration.

With its optimized and reliable holding force, the eT-Gripper product family from euroTECH is suitable for use in various industries and sectors. Users benefit from the euroTECH modular system with its large number of combination and add-on systems. The vacuum specialist supplies both standard and customized vacuum grippers for a wide range of applications. When many parts have to be sawn, laser-cut or punched out of a panel and then separated, manual removal of the individual parts is often very laborious and time-consuming.

This task can be made easy with the help of vacuum technology. For use in a nesting system, euroTECH has developed a special-sized suction box from the eT-Gripper product family that works in combination with a robot.

The suction box, built for a renowned furniture manufacturer and glass processor, is made of aluminum and is used on a robot. It removes a complete layer of cut furniture components from a nesting system and places them ready for sorting and further processing.

Thanks to the bellows suction cups, the eT-Gripper is able to separate a wide variety of shapes from the ten to twelve millimeter thick chipboard. Round parts are just as unproblematic as straight drawer fronts. Even larger parts, such as doors, are no problem for the suction box, as it has dimensions of 800 x 2400 millimetres and is therefore considerably larger than its eT-Gripper family members. A total of 999 BSC 32 E bellows suction cups were installed in it.

The bellows vacuum cleaners are preferable to a suction mat for this task, as they can be operated individually depending on the shape of the part to be vacuumed. This means that any material around the parts that is not required is not sucked up, remains in place and can simply be disposed of once all the parts have been removed.

Despite the enormous size of the suction box, its weight was kept relatively low by using a thin profile. In conjunction with the design of the customer's robot holder and the suction box itself, it is able to hold a maximum of 80 kg in this configuration.

With its optimized and reliable holding force, the eT-Gripper product family from euroTECH is suitable for use in various industries and sectors. Users benefit from the euroTECH modular system with its large number of combination and add-on systems. The vacuum specialist supplies both standard and customized vacuum grippers for a wide range of applications. When many parts have to be sawn, laser-cut or punched out of a panel and then separated, manual removal of the individual parts is often very laborious and time-consuming.

This task can be made easy with the help of vacuum technology. For use in a nesting system, euroTECH has developed a special-sized suction box from the eT-Gripper product family that works in combination with a robot.

The suction box, built for a renowned furniture manufacturer and glass processor, is made of aluminum and is used on a robot. It removes a complete layer of cut furniture components from a nesting system and places them ready for sorting and further processing.

Thanks to the bellows suction cups, the eT-Gripper is able to separate a wide variety of shapes from the ten to twelve millimeter thick chipboard. Round parts are just as unproblematic as straight drawer fronts. Even larger parts, such as doors, are no problem for the suction box, as it has dimensions of 800 x 2400 millimetres and is therefore considerably larger than its eT-Gripper family members. A total of 999 BSC 32 E bellows suction cups were installed in it.

The bellows vacuum cleaners are preferable to a suction mat for this task, as they can be operated individually depending on the shape of the part to be vacuumed. This means that any material around the parts that is not required is not sucked up, remains in place and can simply be disposed of once all the parts have been removed.

Despite the enormous size of the suction box, its weight was kept relatively low by using a thin profile. In conjunction with the design of the customer's robot holder and the suction box itself, it is able to hold a maximum of 80 kg in this configuration.

With its optimized and reliable holding force, the eT-Gripper product family from euroTECH is suitable for use in various industries and sectors. Users benefit from the euroTECH modular system with its large number of combination and add-on systems. The vacuum specialist supplies both standard and customized devices.

Characters incl. spaces: 2,312, reprint free, 4 images